Kayayyaki

Abun Ƙarƙashin Ƙarƙashin Farin Fused Alumina Grits

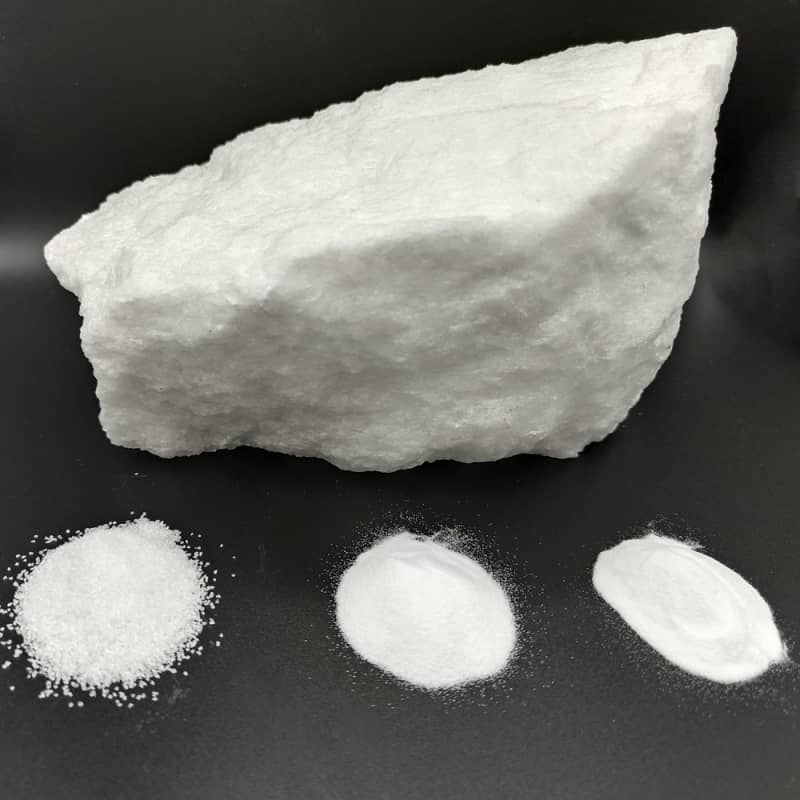

Farin Fused alumina shine alumina foda azaman albarkatun ƙasa, akai-akai sama da 2000 ℃ babban zafin jiki mai narkewar wutar lantarki, bayan fashe filastik, rabuwar maganadisu zuwa baƙin ƙarfe, allon ya kasu kashi iri-iri na girman barbashi, rubutu mai yawa, babban taurin, granular nau'in taurin kusurwa. Ya fi launin ruwan kasa fused alumina yana da ɗan ƙaramin ƙarfi, ɗan ƙaramin ƙarfi, ƙarfi mai ƙarfi da kwanciyar hankali na sinadarai yana da kyau, yana da kyakkyawan rufi.

Farar fused alumina an yi shi da ƙarancin ƙarancin sodium alumina foda mai tsafta ta narkewa a babban zafin jiki, sanyaya crystallization, sannan murkushewa.Farin grit ɗin alumina mai haɗe-haɗe yana ƙarƙashin kulawa mai ƙarfi don kiyaye girman rabon hatsi da daidaitaccen bayyanar.

Yawanci ana amfani da su a cikin tukwane, kayan gudu na ƙarfe, kayan haɗaɗɗun gunning da sauran samfuran refractory na monolithic;

Domin siffa refractory kayan, shi ne yafi amfani a high quality-kayan albarkatun na corundum bulo, corundum mullite, refining karfe porous toshe tubali, na hade SPRAY gun, steelmaking da ci gaba da simintin masana'antu.

Hakanan za'a iya amfani dashi azaman kayan aikin goge baki, simintin gyare-gyare, feshi da sutura, tukwane na musamman

Farar fata, α crystal akan 99%, babban tsabta, babban taurin, da tauri mai ƙarfi, ƙarfin yanke mai ƙarfi, kwanciyar hankali mai ƙarfi, da ƙarfi mai ƙarfi.

| Mohs taurin | 9 |

| Yawan yawa | 1.75-1.95g/cm3 |

| Musamman nauyi | 3.95g/cm 3 |

| Girman girma | 3.6 |

| Digiri na narkewa | 2250 ℃ |

| Digiri na refractory | 2000 ℃ |

Ana amfani dashi don refractory, castable

| Kayayyaki | 0-1 1-3 3-5m/m | F100F200F325 | |||

| Garanti Darajar | Mahimmanci Na Musamman | Garanti Darajar | Mahimmanci Na Musamman | ||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na 2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

Ana amfani dashi don abrasives, fashewa, niƙa

| Nau'in Kayayyakin | hatsi | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Garanti Darajar | Mahimmanci Na Musamman | ||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na 2O | ≤0.30 | 0.2 | |

Ana amfani da abrasives, lapping, goge

| Nau'in Kayayyakin | Micropowder | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230F240F280F320F360F400F500F600F800F1000F1200F1500F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 10000# 80000 | |||

| Garanti Darajar | Mahimmanci Na Musamman | |||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na 2O | ≤0.4 | 0.25 | ||

1.Babu tasiri game da launi na sassan da aka sarrafa.

2.It za a iya amfani da a cikin matakai inda baƙin ƙarfe foda saura ne tsananin haramta.

3.Shaping hatsi suna da matukar dacewa da rigar sandblasting da polishing ayyukan.

1.Yashi, gogewa da nika karfe da gilashi.

2.Filling na fenti, lalacewa-resistant shafi, yumbu, da glaze.

3.Making na nika dabaran, sandpaper da Emery zane.

4.Production na yumbu tace membranes, yumbu tubes, yumbu faranti.

5.Don amfani da bene mai jurewa.

6.Yashi na allon kewayawa.

7.Yashi fashewar jiragen ruwa, injinan jirgin sama, hanyoyin jirgin kasa da na waje.

8.Various farin fused aluminum oxide hatsi za a iya samar bisa ga abokan ciniki' daban-daban bukatun.

Tambayar ku

Idan kuna da wasu tambayoyi. Don Allah jin daɗin tuntuɓar mu.