Kayayyaki

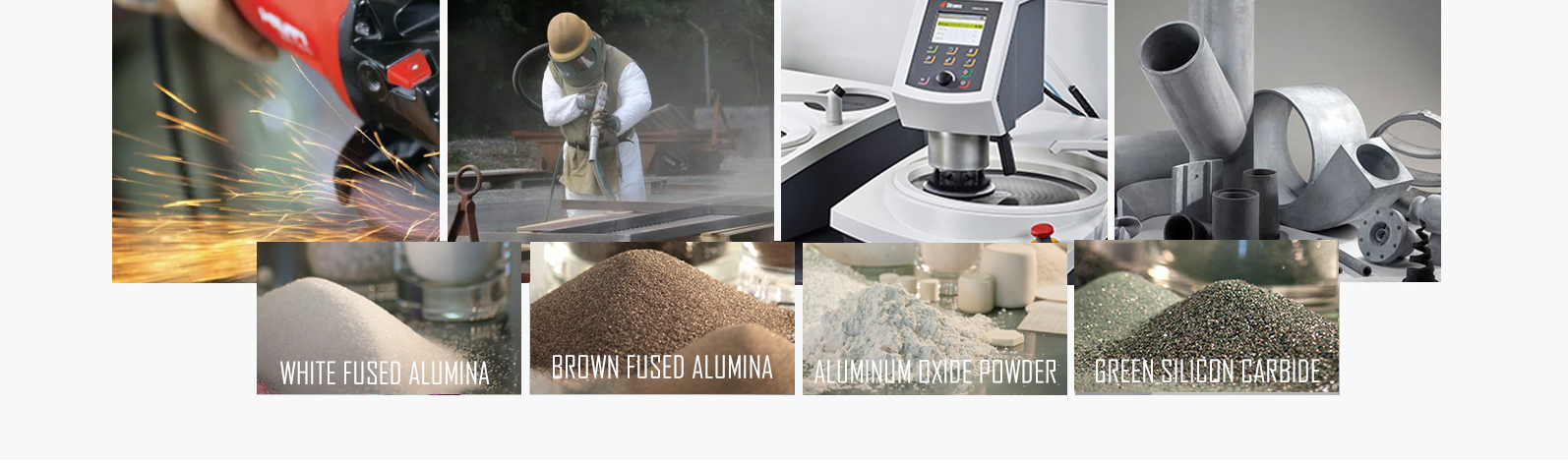

F12-F220 Farin Fused Alumina Oxide Grits

Farin alumina

Farar fused alumina an yi shi da ƙarancin-sodium alumina foda mai tsafta ta narkewa a babban zafin jiki, sanyaya crystallization, sannan murkushe. Farin grit ɗin alumina mai haɗe-haɗe yana ƙarƙashin kulawa mai ƙarfi don kiyaye girman rabon hatsi da daidaitaccen bayyanar.

Whiet Fused Alumina Properties

Farar fata, α crystal akan 99%, babban tsabta, babban taurin, da tauri mai ƙarfi, ƙarfin yanke mai ƙarfi, kwanciyar hankali mai ƙarfi, da ƙarfi mai ƙarfi.

| Mohs taurin | 9 |

| Yawan yawa | 1.75-1.95g/cm3 |

| Musamman nauyi | 3.95g/cm 3 |

| Girman girma | 3.6 |

| Digiri na narkewa | 2250 ℃ |

| Digiri na refractory | 2000 ℃ |

| Ana amfani dashi don refractory, castable | |||||

| Kayayyaki | 0-1 1-3 3-5m/m | F100F200F325 | |||

| Garanti Darajar | Mahimmanci Na Musamman | Garanti Darajar | Mahimmanci Na Musamman | ||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na 2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

| Ana amfani dashi don abrasives, fashewa, niƙa | |||

| Kayayyaki | hatsi | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Garanti Darajar | Mahimmanci Na Musamman | ||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na 2O | ≤0.30 | 0.2 | |

| Ana amfani da abrasives, lapping, goge | ||||

| Kayayyaki | Micropowder | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230F240F280F320F360F400F500F600F800F1000F1200F1500F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 10000# 80000 | |||

| Garanti Darajar | Mahimmanci Na Musamman | |||

| Haɗin Sinadari | Farashin 2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na 2O | ≤0.4 | 0.25 | ||

1.Yashi, gogewa da nika karfe da gilashi.

2.Filling na fenti, lalacewa-resistant shafi, yumbu, da glaze.

3.Yin dutsen mai, dutsen niƙa, dabaran niƙa, takarda yashi da rigar emery.

4.Production na yumbu tace membranes, yumbu tubes, yumbu faranti.

5.Production na polishing ruwa, m kakin zuma da ruwa kakin zuma.

6.Don amfani da bene mai jurewa.

7.Advanced nika da polishing na piezoelectric lu'ulu'u, semiconductors, bakin karfe, aluminum da sauran karafa da wadanda ba karafa.

8.Takaddun bayanai da abun da ke ciki

Tambayar ku

Idan kuna da wasu tambayoyi. Don Allah jin daɗin tuntuɓar mu.