Ƙirƙirar Ƙirƙirar Ƙarfafawa da Ƙirƙirar Ƙarfafawa: Tattaunawa game da Aiwatar da Molds Bayan Ƙirar Mashin

Masana'antun masana'antu na zamani sun gabatar da buƙatu mafi girma don daidaito, inganci da yancin ƙira. Baya ga fasahar kere kere na gargajiya (kamar niƙa, niƙa, da sauransu),masana'anta ƙari (bugu na 3D)fasahar kuma tana bullowa cikin sauri kuma tana zama muhimmiyar hanyar kera sabbin abubuwa. Dukansu suna da nasu fa'idodin kuma ana amfani da su sosai a fannonin motoci, sararin samaniya, na'urorin likitanci da kera injina. A cikin waɗannan hanyoyin masana'antu guda biyu, rawar ƙira yana da mahimmanci musamman kuma yana da alaƙa kai tsaye ga ingancin sarrafawa da ingantaccen samarwa.

Gabatarwa zuwa Fasahar Ƙirƙirar Ƙarfafawa da Aikace-aikacen Mold

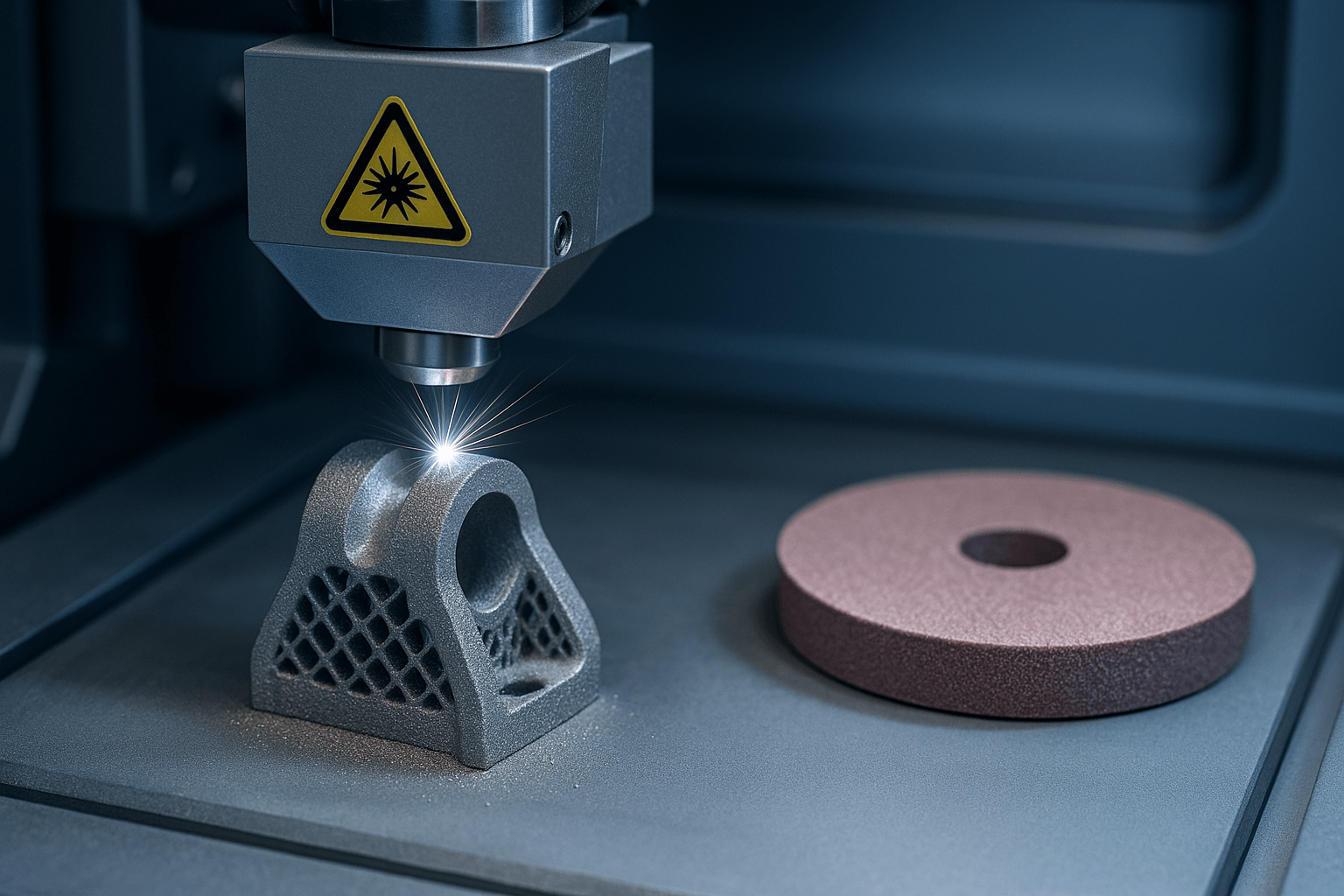

Ƙarfafa masana'antu, wanda kuma aka sani da bugu na 3D, tsari ne na ginin sassa ta hanyar tara kayan Layer Layer. Fasahar masana'anta na gama gari sun haɗa da zaɓin Laser sintering (SLS), narkewar Laser zaɓi (SLM), ƙirar ƙira (FDM) da stereolithography (SLA). An san wannan nau'in fasaha don ƴancin ƙira sosai. Yana iya kera sassa masu hadaddun sifofi da ramukan ciki ko tsarin grid, tare da babban amfani da kayan aiki da rage sharar kayan abu sosai. Ƙarfafa masana'anta ya dace musamman don yin samfuri cikin sauri, ƙananan samar da tsari da keɓancewa na musamman, kuma ana amfani da shi sosai a sararin samaniya, motoci, kayan aikin likita da masana'anta. Fa'idodinsa kuma sun haɗa da rage sake zagayowar ci gaba, haɓaka ƙira mai ƙima da fahimtar hanyoyin magance iri-iri.

Ko da yake masana'anta ƙari na iya samar da hadaddun sifofi kai tsaye, saman ɓangarorin da aka buga yawanci ƙaƙƙarfa ne, tare da layin layi da ƙananan lahani, kuma ana buƙatar machining na gaba don biyan buƙatun girma da ingancin saman. A wannan lokacin, abrasives masu inganci sun zama kayan aiki masu mahimmanci. Abrasives kamarniƙa ƙafafun, Sanding bel, m ƙafafun da polishing ƙafafun suna yadu amfani da deburring, surface flattening da kuma gama na ƙari masana'antu sassa don tabbatar da cewa kayayyakin isa masana'antu-sa daidaici da aesthetics. Musamman a fagen sararin samaniya da likitanci, babban buƙatun don ingancin saman da ayyuka sun kori abrasives don ci gaba da haɓaka kayan aiki mai ƙarfi da kayan sawa mai ƙarfi don saduwa da buƙatu na musamman na masana'antar ƙari bayan aiwatarwa.

Gabatarwa zuwa fasahar kere kere da kuma aikace-aikacen ƙura

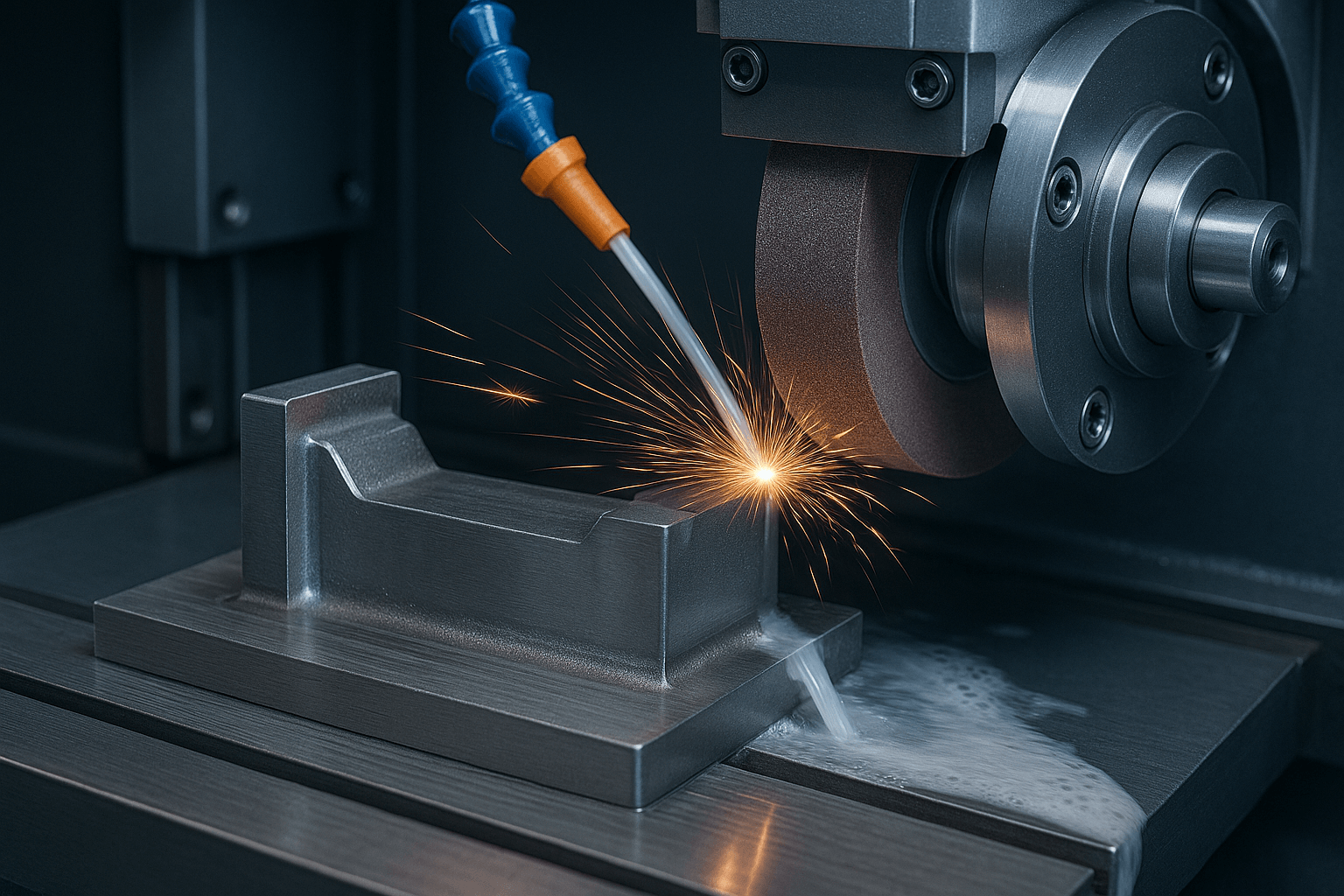

Ƙarfafa masana'antushine cire wuce haddi abu ta hanyar yankan, niƙa, niƙa da sauran hanyoyin aiwatar da workpiece a cikin wani da aka ƙaddara siffar. Wannan fasaha ya balaga kuma ya dace da samar da taro, musamman ma yana da kyau wajen tabbatar da ma'auni mai ma'ana da kuma kyakkyawan yanayi. Hankula matakai sun hada da CNC milling, juya, nika, waya yankan, lantarki sallama machining (EDM), Laser yankan da ruwa jet yankan. Ƙirƙirar ƙira tana taka muhimmiyar rawa wajen samar da motoci, sararin samaniya, masana'antar injina da kayan aikin likita. Yana iya sarrafa ƙarfe da kyau, simintin ƙarfe, aluminum gami da kayan haɗin gwiwa don saduwa da ƙaƙƙarfan buƙatun masana'antu don karɓuwa da aiki.

Abrasives suna taka muhimmiyar rawa a cikin masana'antu masu rahusa, musamman a tsarin niƙa. Daban-daban na niƙa ƙafafun (kamar yumbu nika ƙafafun, guduro bonded ƙafafun nika) da kuma polishing kayayyakin aiki da ake amfani da ko'ina ga m machining, gama da surface polishing bisa ga tsari bukatun don tabbatar da cewa sassa cimma high daidaici da madubi-matakin surface quality. Ayyukan abrasive kai tsaye yana rinjayar ingancin sarrafawa da ingancin samfur, yana haifar da ci gaba da haɓaka sabbin abubuwa da sifofi don saduwa da buƙatun sarrafawa na kayan ɗorewa da hadaddun geometries.

A matsayin muhimmiyar gada tsakanin su biyun, abrasives suna goyan bayan haɗin da ba su da kyau daga masana'anta na ƙari zuwa masana'anta mai rahusa. Tare da haɓaka aikace-aikacen kayan haɗin gwiwa da kayan aiki masu ƙarfi, haɓaka fasahar abrasive ya zama babbar hanyar haɗi don tabbatar da ingancin masana'anta. A mayar da martani ga surface roughness matsaloli na musamman ga ƙari masana'antu da kuma high ainihin bukatun na subtractive masana'antu, da bincike da kuma ci gaban molds ci gaba da ci gaba zuwa mafi girma taurin, mafi tsari da kuma tsawon rai, inganta hankali da kuma yadda ya dace da dukan masana'antu sarkar.