Kayayyaki

Platelet Calcined Alumina Foda

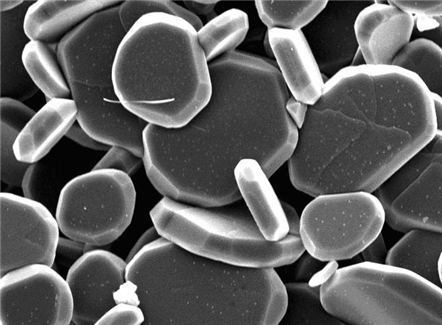

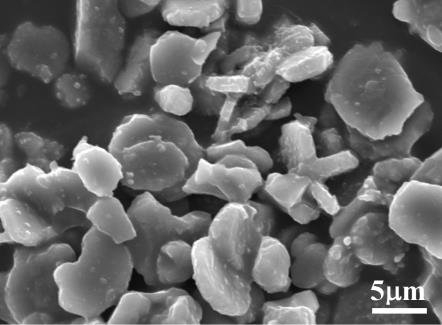

Plate Calcined Alumina polishing foda an yi shi da babban ingancin masana'anta alumina foda azaman albarkatun ƙasa, kuma ana sarrafa shi ta hanyar samarwa ta musamman. Siffar lu'ulu'u na alumina polishing foda da aka samar yana da lebur hexagonal kamar siffar tabular, don haka ana kiranta Platelet Alumina ko Tabular Alumina.

Platelet Alumina babban ingancin alumina nau'in abrasive foda ne, wanda ya ƙunshi kristal mai siffar farantin karfe na Al2O3 tare da tsafta sama da 99.0%. Yana da kyawawan kaddarorin juriya na zafi kamar yadda yake da ƙarancin sinadarai, kuma ba ya lalata ta ko dai acid ko alkalines. Yayin da girman rabon ɓangarorin Platelet Alumina ke sarrafa ta tam, yana iya samar da ƙasa mai kyau sosai, yana ba shi ingantaccen tasiri azaman abrasive. Tare da ɗimbin abubuwan amfani, Platelet Alumina foda ce mai ƙyalli mai iya yin ayyuka da yawa.

Tabular alumina foda

Tabular alumina foda

Madaidaicin Ƙimar Ƙirar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa

| Barbashi | Rarraba ɓarna (µm) | |||

| Matsakaicin barbashi | Girman barbashi | Girman barbashi | Girman barbashi | |

| 45 | 82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | 77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | 64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | 50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | 40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | 32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00± 0.80 |

| 15 | 25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30± 0.50 |

| 12 | 20.2 | 12.8± 1.0 | 8.20± 0.60 | 4.90± 0.40 |

| 9 | 16.0 | 9.70± 0.80 | 6.40± 0.50 | 3.60± 0.30 |

| 5 | 12.7 | 7.20± 0.60 | 4.70± 0.40 | 2.80± 0.25 |

| 3 | 10.1 | 5.20± 0.40 | 3.10± 0.30 | 1.80± 0.30 |

Matsayin inganci

| Nau'in samfur | Takamaiman Nauyi | ||||

| Farashin 2O3 | SiO2 | Fe2O3 | Na 2O | ||

| 3µm-45µm | : 3.90 | 99.0 | 0.20 | 0.10 | 1.00

|

Amfanin Alumina Powder

1. Kwatanta tare da sauran foda foda, tabular alumina foda yana da kyawawan abubuwan haɗin gwiwa. Irin su babban wurin narkewa, ƙarfi mai ƙarfi, ƙarfin injiniya mai ƙarfi, juriya mai kyau, juriya na sinadarai, juriya da iskar shaka da juriya mai zafi da sauransu.

2. Flat takardar siffar sa gogayya girma, inganta nika gudun da kuma yadda ya dace, wannan zai iya rage yawan nika inji, aiki da kuma nika lokaci.

3. Flat takardar siffar sa abu niƙa ba sauki a karce, da kudi na m kayayyakin iya ƙara 10% -15%. Misali, ƙimar ƙwararrun wafer silicon wafer na iya kaiwa zuwa 96% ko fiye.

4. Yana da sau biyu sakamakon nano da micro powders, da surface aiki ne matsakaici, ba kawai zai iya yadda ya kamata hada tare da sauran aiki kungiyoyin, amma kuma ba sauki ga agglomerate da sauƙaƙe m watsawa.

5. Yana da mannewa mai kyau, tasirin kariya mai mahimmanci da ikon yin haske.

6. The tabular alumina foda ya kusan m, mara launi, kuma yana da lebur da santsi. Da lu'ulu'u mai kyau na lu'ulu'u ne na yau da kullun hexagons na yau da kullun.

7. The tabular alumina foda za a iya sanya a cikin kyau kwarai polishing foda.

1. Electronics masana'antu: nika da polishing na semiconductor monocrystalline silicon wafers, ma'adini ma'adini lu'ulu'u, fili semiconductors (crystalline gallium, phosphating nano).

2. Glass masana'antu: nika da kuma aiki na crystal, ma'adini gilashin, kinescope gilashin harsashi allon, Tantancewar gilashin, ruwa crystal nuni (LCD) gilashin substrate, da ma'adini crystal.

3. Coating masana'antu: na musamman coatings da fillers ga plasma spraying.

4. Karfe da yumbu masana'antu: madaidaicin yumbu kayan aiki, sintered yumbu albarkatun kasa, high-sa high-zazzabi coatings, da dai sauransu.

Tambayar ku

Idan kuna da wasu tambayoyi. Don Allah jin daɗin tuntuɓar mu.